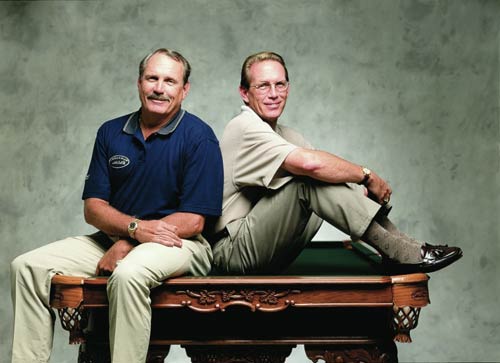

The Olhausen Story

In 1973, brothers Butch and Donny Olhausen bought a small manufacturing company in San Diego, California. The company they bought was making about 35 pool tables annually. Their first year, their goal was to somehow double the business and sell 70 tables. Olhausen Billiard Manufacturing, Inc. is now selling almost 30,000 tables a year from their 250,000-square-foot facility in Portland, Tennessee.

Still family-owned and operated, Butch, Donny and all the people at Olhausen have consistently pursued a tradition of quality, service, selection and value. These attributes, and four generations in the business, have earned their company the title of "The Best in Billiards."

Olhausen Tables

Contact Us

OlhausenBilliards.com

Olhausen on Manufacturing Marvels

Watch and see how skilled American craftsmen build the 'Best in Billiards'!

Watch on Youtube

Olhausen Craftsmanship

AccuFast Cushions

AccuFast Cushions were developed in 1992 by Olhausen Billiards and VIP Rubber. Olhausen sent surveys to their consumer base and asked what they could do to improve their product. Standard billiard table cushion rubber was developed in 1880, and the recipe has really not changed since. Olhausen’s exclusive AccuFast Cushions are made of the finest grade 100% pure Gum Rubber. There are no fillers used and the rubber is 100% bonded to the pool table rail. Changes in temperature do not affect the play of the ball off the cushion. AccuFast comes with a true Lifetime Warranty. Over 500,000 sets on the marketplace today and Olhausen has yet to need to replace a set under warranty. Cheaper imported cushions can “go bad,” and the life expectancy can be as little as 7 to 10 years. Replacing dead cushions can cost as much as $700 to $1000 with labor and cloth. AccuFast Cushions are 100% Made in the USA.

True Lifetime Warranty

The majority of pool tables in the marketplace are made overseas. When the manufacturer discontinues a model or finish, what kind of warranty do you truly have? Are they going to make you a matching part? And, in the rare event they are willing to do so, how long will it take to get made and shipped? Olhausen still makes parts and pieces for table manufactured 40 years ago! If you have a bad part all they ask is you send in the part so they can match the stain and they will produce the part and stain it to match the rest of your pool table. How much is that peace of mind worth?

Finish

The Tempered Varnish Finish, which is proprietary to Olhausen, is a process where the finish is heated and cooled over a 7 step process. It is UV resistant and will not yellow or scratch. In fact, a tempered varnish finish is so hard that you can dent the wood without affecting the finish. Not that we recommend this, but you could pour a soda on it and wipe it off the next day and there will be no water ring marks! If the finish were to ever start peeling, cracking or clouding it is covered under the Lifetime Warranty. And unlike most of the competitors in the marketplace, Olhausen finishes the whole pool table in the Tempered Varnish Finish. Additionally, Olhausen offers over 30 different finishes and will even match a customer’s finish if requested!

Olhausen Finish OptionsConstruction

Olhausen’s Uni-liner Construction ties the frame together at all points and increases the slate support area, decreasing the reliance on shims to level the table and ensuring the table will support a level playfield. In 2001 Weyerhaeuser tested Olhausen Uni-liner construction versus the competitor’s center beam construction. It was proven that the Uni-liner and not the length of the center braces created a stronger table.

Quality Control

Olhausen cabinet frames are Pre-assembled at the factory. Frames are leveled and squared for precise fit and installation. Most manufacturers ship their tables unassembled and in boxes. These are known as “kit” pool tables and are subject to more human error in assembly. Olhausen frames are triple checked during the manufacturing process and signed by the person that built them, ensuring accountability and quality control throughout the manufacturing process. All tables are built and stained at the same time. Most manufacturers do “runs” where one day they do legs, the next day aprons, etc. How can all the parts truly match this way? At Olhausen, when the frame goes to be stained it is also accompanied by the legs, rails, aprons, etc so it all matches perfectly.